Company Introduction:

DBOIM has already passed the certification of ISO9001:2008 and now is in procedure of passing the external certification by ISO14001:2004 Environmental Manage System.

Currently, DBOIM is running SDP program with BOSCH. Lean Production is carried out in every part of company’s operation. Lean Production focuses on fulfilling the requirement of consumers, saving resources and keeping company’s upgrading, which can effectively reduce the cost and raise the productivity. DBOIM has made huge changes on decreasing the stock level, lead times, resources wasting, as well as increasing the products’ quality after adding Lean Production system in operation. DBOIM is much more competitive than before with this strategy.

Strageties:

(I)5S Management

5s is the core of Lean Production. With 5s management in DBOIM operation, every expect in the workshop spot are in order, with clean working condition the employee raises its productivity and quality while assembling instruments.

5S management

(II)Visual Production

The visual production includes:visible production plan, visible quality status, visible staffs’ skills matrix and visible production line with materials supplying.

Visual Producing

(III)Standardization Production

Standardization Production guarantee the same quality of products from different workers and increase the productivity.

Standardization Production

(IV)Lean Production Line

DBOIM designs the production line with precise calculation of the market requirements which reduce the cost and increase the operation efficiency of their production line. Below are the Lean Production Line we have set up:

Lean Production Line

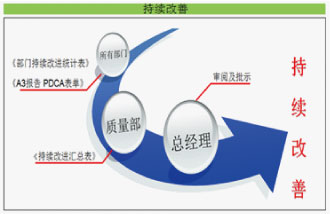

(V)Keep Sustainable Developing Promotion and Practical Sustainable Developing

This is one of speciality of Lean Production. DBOIM keeps this sustainable developing in order to make Lean Production reaching high level.

Keep Improvement

Strictly Quality Control & Procedure Improvement:

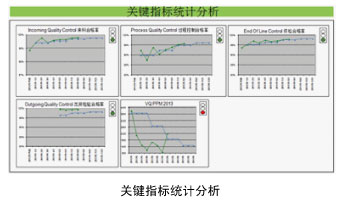

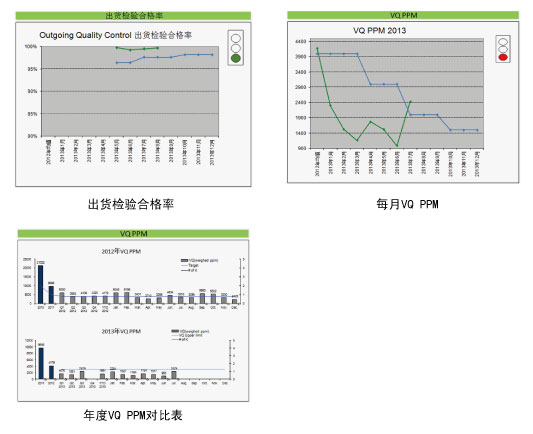

(I) Statistic and Analyzing of the core target

Core target analyzing

(II)Quality control of material supplying

Eligible of material, Supplier Improvement Report (A3) & Supplier's Reply Delaying Table(8D)

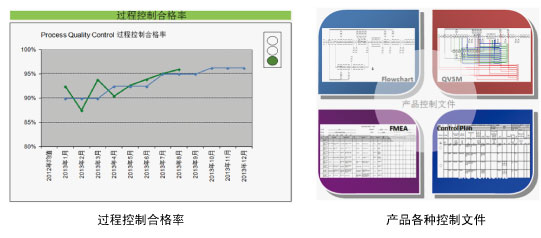

(III)Quality control of producing procedures

Procedure Controling & Related Profiles

(IV)Quality control of final products

Output Products Checking, Monthly VQ PPM & Annualy VQ PPM